hi

Dear All

The readers who has been following my posts on PM ( paper mache ) research( I should really call it casual exploration),knows that I have been writing about the Kashmiri pm crafts and few homemade recipes to achieve that porcelain smooth look...my exploration still continues...

here in this post I want to share some of the tips/Points ( that I have found during the exploration) if you want to get it "right " from the beginning...

I dont know if these tips will be helpful or not in your case ,but I will advice you to explore more..

please go trough my other posts ,if you find these tips "confusing",that will help you to co-relate

sanding must be done after the layer dries completely,and each layer should be sanded smoothly,then only next layer can be applied smoothly.this should be our process beause we dont have factory quality equipments at home,I am yet to try "file" that are used to smooth out metals ...sanding should be done in 3 stages ,gradually moving from bigger grain to finer grain..

to protect the surface craftsmen of Kashmir often use TISSU or butter paper ,as the final layer,in my experience ,it can give a good surface ,if it can be sanded again..

many artists boils toilet paper to the point ,and keep soaked a day or two before using,these extreme treatement often make the paper so creamy so that it could be squeezed through a strainer,people who don't have hand blender or a mixer ,can use this method,I am yet to do it.

I have read in Kashmir Pm craft ,cloth and saw dust are used,to make to bonding good,we can easily do it in our home.many foreign sites have used "wood filler" for their projects,I never found such thing in our local market ,actually we fill wood in a old-school manner,hence I had to use saw dust -it works

always use a pallet knife or a blunt knife-like object to smooth the clay out when its wet-the smoother it is from the beginning --you have less headache afterwards-like sanding.sanding can be a very boring process,unless you use a electric sander,that's a luxury for me!

I had mentioned in my other posts that ,saresh -a laquare ,rubbery glue they use to join the cut -we can use our glue gun-it works

I used acrylic distemper in one of my project as final coat,Its thicker than the gesso,thinner than the putty,and its too runny,--now use your best judgement

Kashmir"s craftsmen,use a burnt brick or pumice stone,to sand the surface smooth-the pumice stone that I had ,was bought from a beauty supply store ,I must tell,it got sanded mode than it actullly sanded LOL!! i know pumice are soft stone ,but...anyway am not done with it ,one bad experience should not discourage me.

Remember I am a beginner,I may have made mistakes,hence your advice solicited.

after this experiment I have formulated another pm clay,I will talk about it some other time..

till then bye

Saturday, February 14, 2015

Thursday, February 12, 2015

Tuesday, February 10, 2015

Monday, February 9, 2015

Sunday, February 8, 2015

Saturday, February 7, 2015

Home Made Paper Mache Clays :my findings: tutorial

Dear all

I hope you all have gone through my earlier post on Original Master recipe of paper mache clay ...this is the continuation of the last post ....

lets begin

I hope you can see all the clays after its spread on the news paper.

NEXT MORNING

Pm clay was still wet.for surface smoothness I will give **( 2 stars) out of *****(5 stars)

saw dust clay was also wet,surface smoothness: *

saw dust + pm was not so wet ,surface smoothness:**

pm + chalk was not so wet( damp), for surface smoothness :***

Pm + china clay was dry,smoothness:****

pm+whiting powder was dry ,for smoothness:****

here you may note that ,My aim is to get it smooth from the first stage,no visible bumps and uneven -ness is allowed to happen ,so that we don't have to work hard to make it porcelain -smooth.....that's was the idea I adapted from the beginning-

ok,here I want to add that ,I made news print pm clay earlier for a small project.I was not very happy with the clay after it dried up-it was all bumpy..hence I opted for this idea...some sites even says that news prints contains lead,hence it may not be kid-friendly /environment friendly..

in the evening I tries to sand ( bigger grains) manly those two samples which dried up in the morning,it could be sanded(with out gesso) easily and surface smoothness was satisfactory ...

NEXT MORNING

according to the experts,coating gesso and sanding in between the application, gives to real smoothness..but here I wanted to sand without gesso..

before you sand ,make sure it was completely dry

Pm was smooth enough after sanding ,afterall it was the traditional formula, coverage :***

saw dust was not that smooth ( it was predicted) ,coverage:***

pm+ saw dust: quite smooth,coverage :***

pm+chalk clay :smooth ok,coverage:***

pm+china clay :smooth,coverage :****

pm+Whiting powder:smooth ,coverage :****

note that ,coverage is examined when applied in thin layers

shrinkage rate

Pm ****

saw dust****

pm+ saw dust:***

pm+chalk clay :****

pm+china clay :**

pm+Whiting powder:**

lower number of stars you see,means they have shrink-ed less

now it was a time to choose 2 winners

pm+saw dust

pm+whiting powder

pm+saw dust project made me happy,it was quite smooth,after 2 coats of gesso and sanding the result was good..

here

next projects was a globe

oops!!

happy ...

but search continues

I will be sharing some tips on my next post...

keep creating!!

I hope you all have gone through my earlier post on Original Master recipe of paper mache clay ...this is the continuation of the last post ....

lets begin

I wanted to find out more about pm ,hence these first hand

experiments were done.

My aim is to find a perfect recipe of pm clay which ensures

a porcelain –like smoothness.

As a hobbyist I don’t have that infrastructure to contest with the Kashmiri Craftsmen,still

the hunger of that perfect smoothness is driving me …I know it would be

impossible for me to follow the exact step by step process of the pm crafts of Kashmir,

hence I have designed my experiments in a way so that it can be done in home environment

with the help of some simple easily

available shop-bought tools,I hope it

will work for me ..lets c

After reading about my experiments ,you are welcome to form

your own conclusions,I will be producing some datas here and ofcourse my

opinion on that..if you have any questions,please feel free to communicate

through the comment section.

WEATHER CONDITION

When I am doing these experiments its winter time,it takes

longer than usual to dry up…my preference is with warm weather..

CONTESTANTS

1.

PM clays ------credit goes to Jonni Good

2.

Saw dust clay-------I know its not related to pm

but ,I gave it a try,credit goes to a Russian blog , I cant pronounce the

name.LOL

3.

Pm+ saw dust--------credit goes to me

4.

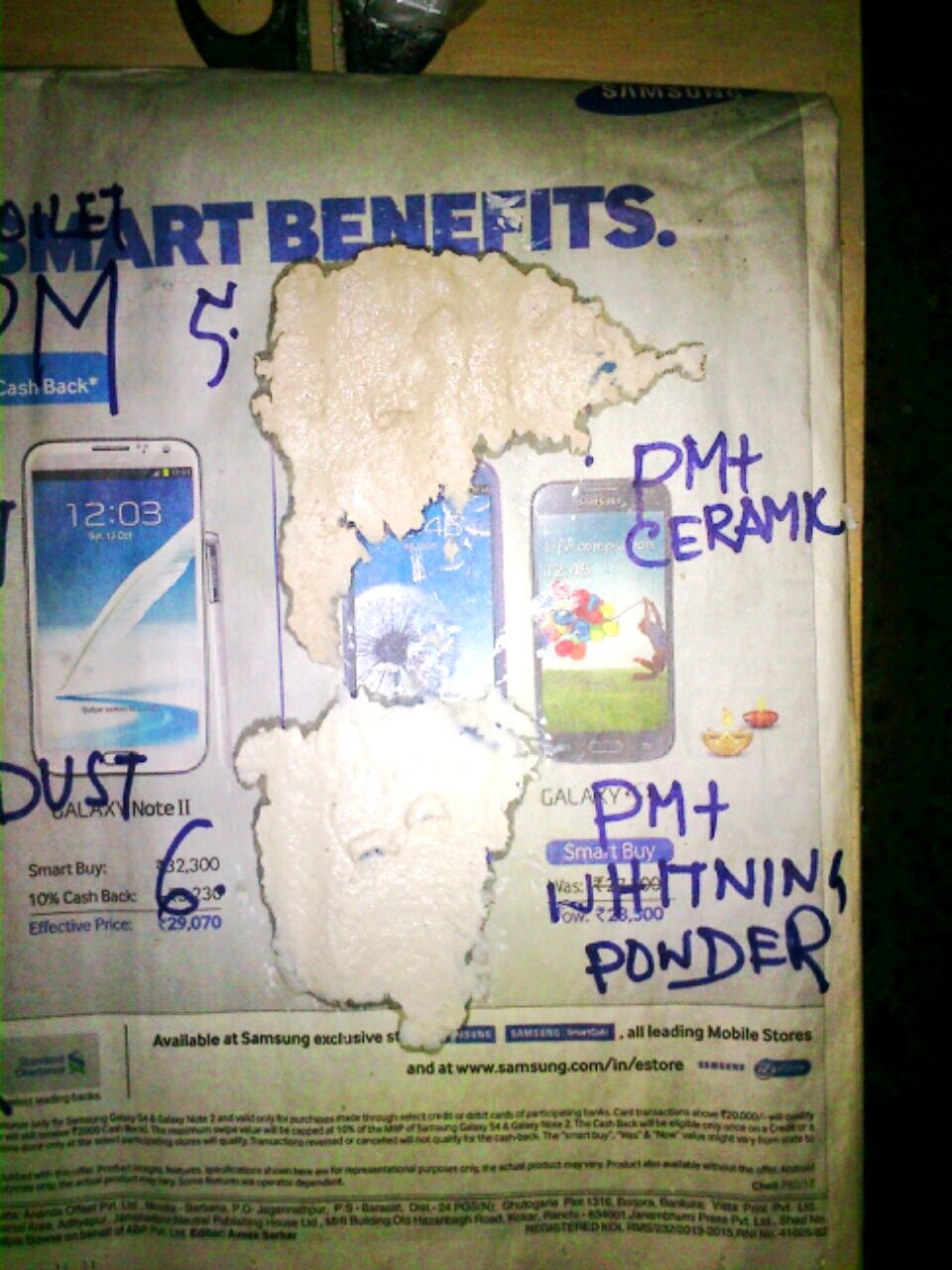

Pm+ china clay ( ceramic powder) credit goes to Jonni

5.

Pm+ whiting powder ----- credit goes to me

6.

Pm+chalk powder----I have read that few people

use it for extra smooth ness

I must tell you there can be hundreds of combinations

,recipes –use your imagination,it may happen that all these 6 formulas fail,you

may even get to discover a completely different recipe …lets explore

since news papers will be the main "base" material,I applied 6 of these one by one on a news paper.

since news papers will be the main "base" material,I applied 6 of these one by one on a news paper.

I hope you can see all the clays after its spread on the news paper.

NEXT MORNING

Pm clay was still wet.for surface smoothness I will give **( 2 stars) out of *****(5 stars)

saw dust clay was also wet,surface smoothness: *

saw dust + pm was not so wet ,surface smoothness:**

pm + chalk was not so wet( damp), for surface smoothness :***

Pm + china clay was dry,smoothness:****

pm+whiting powder was dry ,for smoothness:****

here you may note that ,My aim is to get it smooth from the first stage,no visible bumps and uneven -ness is allowed to happen ,so that we don't have to work hard to make it porcelain -smooth.....that's was the idea I adapted from the beginning-

ok,here I want to add that ,I made news print pm clay earlier for a small project.I was not very happy with the clay after it dried up-it was all bumpy..hence I opted for this idea...some sites even says that news prints contains lead,hence it may not be kid-friendly /environment friendly..

in the evening I tries to sand ( bigger grains) manly those two samples which dried up in the morning,it could be sanded(with out gesso) easily and surface smoothness was satisfactory ...

NEXT MORNING

according to the experts,coating gesso and sanding in between the application, gives to real smoothness..but here I wanted to sand without gesso..

before you sand ,make sure it was completely dry

Pm was smooth enough after sanding ,afterall it was the traditional formula, coverage :***

saw dust was not that smooth ( it was predicted) ,coverage:***

pm+ saw dust: quite smooth,coverage :***

pm+chalk clay :smooth ok,coverage:***

pm+china clay :smooth,coverage :****

pm+Whiting powder:smooth ,coverage :****

note that ,coverage is examined when applied in thin layers

shrinkage rate

Pm ****

saw dust****

pm+ saw dust:***

pm+chalk clay :****

pm+china clay :**

pm+Whiting powder:**

lower number of stars you see,means they have shrink-ed less

now it was a time to choose 2 winners

pm+saw dust

pm+whiting powder

pm+saw dust project made me happy,it was quite smooth,after 2 coats of gesso and sanding the result was good..

here

next projects was a globe

oops!!

happy ...

but search continues

I will be sharing some tips on my next post...

keep creating!!

Friday, February 6, 2015

Original paper mache clay : my findings : tutorial

hi

dear all

You can see that I have been posting paper mache ( now on I will use "pm")crafts,which is a new thing I am experimenting with.I am totally enjoying this versatile medium-and many ideas are popping now and then in my head ,I hope to try my hands on those one by one...

As you know -the site ,ULTIMATE PAPER MACHE.COM have been a great help to the pm beginners-I have got all the necessary basic infos from this wonderful site ,Thank you JONNI, and another site that I want to mention about is ,actually its a forum ,called PAPER- MACHE UK. here other pm enthusiasts are very helpful,they help you out as soon as you post your questions -thank you all the people for you help..

Internet is a magical place where you will get all sorts of inspiration-often artists share their techniques with all of us,thanks to them..but I have felt ,different people has different types of process/techniques --what i meant is ,what works for me ,it may not work for others-the type of finishing I like ,it may not be the liking of others -hence I tried to work on/find out different processes just to see which one works for me..right?

Kashmir(INDIA)has a great legacy of making PM crafts for centuries...they have excelled in it,personally I think nobody can beat their craftsmanship.the hard work and craftsmanship they put in it is ,just amazing..I started my journey of pm from here , by understanding the master-class..

you will get many sites which will tell you briefly about this process.I don't expect sites to spell it word by word,after all its their trade secret..what "PICTURE" I got from studying different texts is ,in a nut shell

paper,mostly waste paper is soaked in water for 3/4 days till the fibers are disintegrated,then its pounded in a stone vessel,sun dried,mixed with a glue ( made of rice and glue boiled in water=here "starch" is a point),

then these people use moulds ,first the mould is covered with ordinary paper ,then this pm clay paste is applied,after it dries up,moulds are cut with a saw along the center line ,the paper object (now cut in half ) are joined by a thick glue -SARESH,a kind of a laquare (natural gum +sugar)

then ,its time to smooth out the surface ,they use a burnt brick or a pumice stone ,then a layer of SARESH is applied ,again on which chuna (pumice) paste /glue+gypsum is applied .again the smoothing occurs,finally tissu or butterpaper is used to protect the surface .

I bought a pm kashmiri chrishtmas ball,just to see my self what is used inside...

here you see ,I have cut the ball in half ,lets see whats inside..

now you can see , where the craftsman had cut .

now more closer look

here we can see the SARESH,the glue/laquare ( all purpose)

its a rubbery and brown in colour,very hard..here i want to mention that ,the thickness of this ball is around 1/4 inch( approximate)

quite hard, even if I squeeze it in my hand ,happens nothing, I think its the starch of rice and glue makes its super-duper hard/stiff

now its time to see what types of paper or pm clay they use,

paper that was used in moulds initially is a normal news paper ,very cheap...

after that the actual pm clay is layered,I must say I could not understand/recognize a single particle of that mass,it is so well mutilated that its hard to believe that it has a paper in it.

during my research time at net ,I read some where wood particles(saw dust ) cloth-fibre and other mislenious stuffs are used to make the pm clay solid,u know what I mean....as write this blog, I feel that I should have seen it under the microscope...anyway, actully the stuff that has been used for making this clay is mixed with rice starch and glue in such a high temperature ,that its totally lost its character....lets move on

just imagine the craftmanship..

you may ask ,why I did this elaborate study?it was done to get inspired by masters..I want to get this same effects in my papaer mache crafts -thats it...

hence my research continues...

on my next post ,I wish to share some of the home made paper clay recipe ,which may /may not help you get the porcelain smooth finish ..

stick with me to know about my next experiment...

lets explore..

enjoy

dear all

You can see that I have been posting paper mache ( now on I will use "pm")crafts,which is a new thing I am experimenting with.I am totally enjoying this versatile medium-and many ideas are popping now and then in my head ,I hope to try my hands on those one by one...

As you know -the site ,ULTIMATE PAPER MACHE.COM have been a great help to the pm beginners-I have got all the necessary basic infos from this wonderful site ,Thank you JONNI, and another site that I want to mention about is ,actually its a forum ,called PAPER- MACHE UK. here other pm enthusiasts are very helpful,they help you out as soon as you post your questions -thank you all the people for you help..

Internet is a magical place where you will get all sorts of inspiration-often artists share their techniques with all of us,thanks to them..but I have felt ,different people has different types of process/techniques --what i meant is ,what works for me ,it may not work for others-the type of finishing I like ,it may not be the liking of others -hence I tried to work on/find out different processes just to see which one works for me..right?

Kashmir(INDIA)has a great legacy of making PM crafts for centuries...they have excelled in it,personally I think nobody can beat their craftsmanship.the hard work and craftsmanship they put in it is ,just amazing..I started my journey of pm from here , by understanding the master-class..

you will get many sites which will tell you briefly about this process.I don't expect sites to spell it word by word,after all its their trade secret..what "PICTURE" I got from studying different texts is ,in a nut shell

paper,mostly waste paper is soaked in water for 3/4 days till the fibers are disintegrated,then its pounded in a stone vessel,sun dried,mixed with a glue ( made of rice and glue boiled in water=here "starch" is a point),

then these people use moulds ,first the mould is covered with ordinary paper ,then this pm clay paste is applied,after it dries up,moulds are cut with a saw along the center line ,the paper object (now cut in half ) are joined by a thick glue -SARESH,a kind of a laquare (natural gum +sugar)

then ,its time to smooth out the surface ,they use a burnt brick or a pumice stone ,then a layer of SARESH is applied ,again on which chuna (pumice) paste /glue+gypsum is applied .again the smoothing occurs,finally tissu or butterpaper is used to protect the surface .

I bought a pm kashmiri chrishtmas ball,just to see my self what is used inside...

here you see ,I have cut the ball in half ,lets see whats inside..

now you can see , where the craftsman had cut .

now more closer look

here we can see the SARESH,the glue/laquare ( all purpose)

its a rubbery and brown in colour,very hard..here i want to mention that ,the thickness of this ball is around 1/4 inch( approximate)

quite hard, even if I squeeze it in my hand ,happens nothing, I think its the starch of rice and glue makes its super-duper hard/stiff

now its time to see what types of paper or pm clay they use,

paper that was used in moulds initially is a normal news paper ,very cheap...

after that the actual pm clay is layered,I must say I could not understand/recognize a single particle of that mass,it is so well mutilated that its hard to believe that it has a paper in it.

during my research time at net ,I read some where wood particles(saw dust ) cloth-fibre and other mislenious stuffs are used to make the pm clay solid,u know what I mean....as write this blog, I feel that I should have seen it under the microscope...anyway, actully the stuff that has been used for making this clay is mixed with rice starch and glue in such a high temperature ,that its totally lost its character....lets move on

just imagine the craftmanship..

you may ask ,why I did this elaborate study?it was done to get inspired by masters..I want to get this same effects in my papaer mache crafts -thats it...

hence my research continues...

on my next post ,I wish to share some of the home made paper clay recipe ,which may /may not help you get the porcelain smooth finish ..

stick with me to know about my next experiment...

lets explore..

enjoy

Wednesday, February 4, 2015

Monday, February 2, 2015

pepar mache ; tiki inspired

dear All

enjoying these last days of winter ..and experimenting with Paper Mache..

This was inspired by Tiki mask.this is my first attempt ,hence learning a lot form my own experience..

let me know what do you think?

enjoying these last days of winter ..and experimenting with Paper Mache..

This was inspired by Tiki mask.this is my first attempt ,hence learning a lot form my own experience..

let me know what do you think?

Sunday, February 1, 2015

pepar mache apple 2

hi

this is my 2nd attempt of making another PM ( red )apple

i am always obsessed with the smoothness when working with paper mache..i am happy with this result...i had mixed little bit of saw-dust in to the regular paper mache.

enjoy

this is my 2nd attempt of making another PM ( red )apple

i am always obsessed with the smoothness when working with paper mache..i am happy with this result...i had mixed little bit of saw-dust in to the regular paper mache.

enjoy

Subscribe to:

Comments (Atom)